Electroplating & Electroless Plating: Advanced Surface Coating Solutions for Durability and Precision

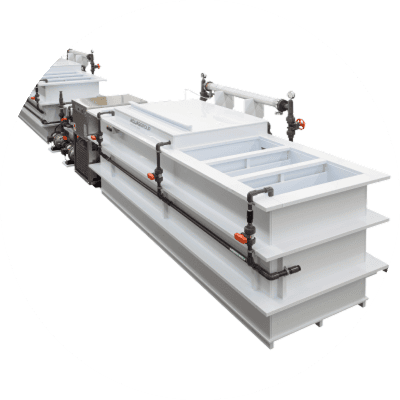

Both electroplating and electroless plating are critical techniques for enhancing the surface properties of metal parts. These processes provide essential benefits, including improved corrosion resistance, increased hardness, and enhanced aesthetic finishes. AQUASGROUP designs and builds electroplating and electroless plating systems tailored to meet the specific requirements of industries such as automotive, aerospace, electronics, and industrial manufacturing.

- Pre-Treatment: Parts undergo cleaning and surface preparation to remove contaminants and ensure proper adhesion of the plating material. This may include chemical cleaning, abrasive blasting, or other surface conditioning methods.

- Electrolytic Bath: Parts are immersed in a bath containing the plating material (e.g., gold, nickel, chrome, copper) and an electrical current is passed through. The electrochemical reaction causes metal ions to deposit uniformly onto the surface of the part.

- Post-Treatment: The plated parts may undergo additional processes such as polishing, coating, or curing to enhance surface finish and durability.

- Pre-Treatment: Similar to electroplating, parts are thoroughly cleaned to remove contaminants and prepare the surface for plating.

- Chemical Bath: Unlike electroplating, electroless plating does not require an external electrical current. Instead, a chemical reaction reduces metal ions in the bath, causing them to deposit uniformly onto the part surface.

- Curing or Drying: After plating, parts may be subjected to heat treatment to cure the coating, improving its mechanical properties and durability.

- Consistency: Tight control over parameters such as bath temperature, voltage (for electroplating), and plating time ensures consistent coating thickness, preventing defects and ensuring uniformity across all parts.

- Quality: Accurate process control ensures the coating meets specific properties such as corrosion resistance, hardness, and smoothness.

- Efficiency: By reducing the need for rework and ensuring consistent quality, our systems optimize resource usage, reduce energy consumption, and minimize waste.

- Deionized (DI) Water: DI water is essential for rinsing and ensuring the removal of any residual contaminants. Impurities in water can result in defects or reduced adhesion of the plating material.

- Closed-Loop Water Recycling Systems: To reduce environmental impact and operating costs, AQUASGROUP’s electroplating and electroless plating systems feature closed-loop water recycling, minimizing water consumption while maintaining high purity for optimal process control.

Both electroplating and electroless plating offer multiple coating options and can be customized for various industries and applications.

Electroplating Methods

- Nickel Plating: Used for corrosion protection, wear resistance, and hardness. Common in automotive, aerospace, and electronics.

- Chrome Plating: Provides a hard, durable, and shiny finish. Ideal for automotive trim, tooling, and aerospace parts.

- Gold Plating: Offers excellent corrosion resistance and is used for decorative applications, electronic components, and jewelry.

- Copper Plating: Used for electrical conductivity and as an undercoat for other coatings. Common in electronics and circuit board manufacturing.

Electroless Plating Methods

- Nickel Plating: Provides excellent corrosion and wear resistance. Common in automotive, aerospace, and industrial applications.

- Copper Plating: Used primarily in electronics for improving conductivity and for providing a smooth base for further plating processes.

- Silver Plating: Offers high electrical conductivity and is commonly used in electronic components and connectors.

- Gold Plating: Provides excellent conductivity and corrosion resistance, commonly used for high-performance connectors and semiconductor components.

The design of electroplating and electroless plating systems is crucial to achieving optimal results. AQUASGROUP’s systems feature cutting-edge technology to deliver consistent and reliable plating.

- Electrical Control (Electroplating): Precise voltage control ensures even deposition of plating material and uniform thickness.

- Chemical Control (Electroless Plating): Advanced monitoring of bath chemistry (e.g., pH, metal concentration, and temperature) ensures uniform plating quality.

- Agitation Systems: Proper agitation ensures even coating distribution and helps prevent defects such as pitting or uneven coating.

- Temperature Regulation: Maintaining the optimal temperature in the plating bath helps achieve consistent plating properties.

- Automation: AQUASGROUP’s systems incorporate automation to reduce operator intervention, improve consistency, and optimize throughput.

- Customizable Solutions: AQUASGROUP’s systems are tailored to meet the specific needs of each application, whether for automotive, aerospace, electronics, or industrial components.

Electroplating and electroless plating are used in a wide range of industries to enhance surface properties and improve performance. Common applications include:

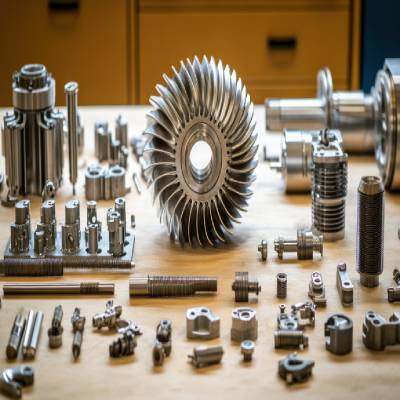

- Automotive: Corrosion protection, wear resistance, and aesthetic finishes for parts like trim, wheels, and engine components.

- Aerospace: High-performance coatings for critical components exposed to extreme conditions.

- Electronics: Plating for circuit boards, connectors, and semiconductors to improve conductivity and performance.

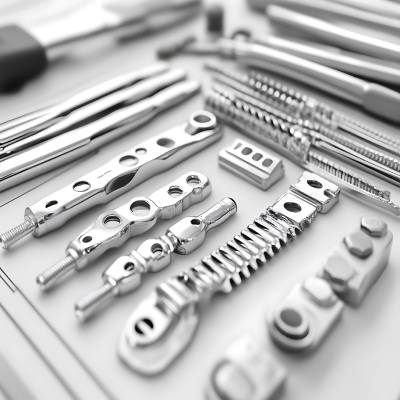

- Medical: Precision coatings for implants, surgical tools, and devices that require biocompatibility and durability.

- Industrial: Plating for tools, machinery, and equipment to improve wear resistance and extend service life.

Achieve Superior Results with AQUASGROUP’s Electroplating & Electroless Plating Systems

AQUASGROUP designs and builds electroplating and electroless plating systems that deliver high-quality results for a wide range of industries. Our systems feature precise process controls, advanced water management, and customizable designs to meet the specific needs of our customers. With AQUASGROUP, you can trust that your electroplating and electroless plating processes will deliver exceptional results, ensuring improved performance, durability, and longevity of your components.

Mailing Address:

Corporate Headquarters & Fabrication Division

41 Commercial Way

East Providence, RI 02914

Water Technologies & Service Division

830 Waterman Avenue

East Providence, RI 02914