Fluorescent Penetrant Inspection: Reliable Detection of Surface Defects

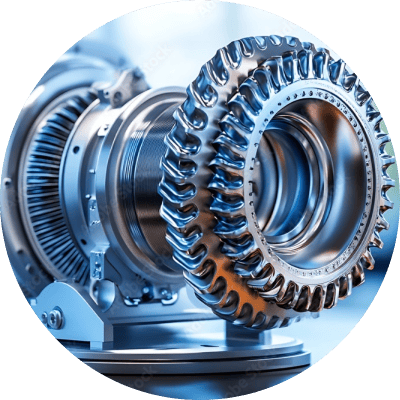

Fluorescent Penetrant Inspection (FPI) is a non-destructive testing (NDT) method used to detect surface-breaking flaws in non-porous materials. Widely used in aerospace, defense, medical, and precision manufacturing industries, FPI reveals cracks, porosity, laps, and other discontinuities that may not be visible to the naked eye. This critical inspection step ensures the structural integrity, reliability, and safety of mission-critical components.

- Pre-Cleaning: The part surface is cleaned to remove oils, debris, or residues that could mask defects.

- Penetrant Application: A fluorescent dye penetrant is applied to the surface and allowed to seep into any surface defects.

- Dwell Time: The part sits for a controlled period, allowing the penetrant to enter any discontinuities.

- Excess Penetrant Removal: The surface is gently cleaned to remove residual penetrant without extracting it from flaws.

- Developer Application: A developer draws penetrant from defects back to the surface, creating visible indications.

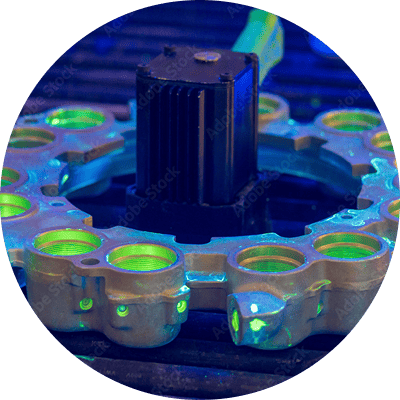

- Inspection Under UV Light: The part is examined under ultraviolet (black) light in a darkened environment, revealing flaws through fluorescence.

- Post-Cleaning: The part is rinsed and dried to prepare it for further processing or return to service.

FPI can be carried out using different techniques depending on the part geometry, material, required sensitivity, and production environment:

- Water-Washable (Method A): The most commonly used method, where excess penetrant is removed with water spray after the dwell time. It’s ideal for high-throughput inspection with robust cleaning capabilities.

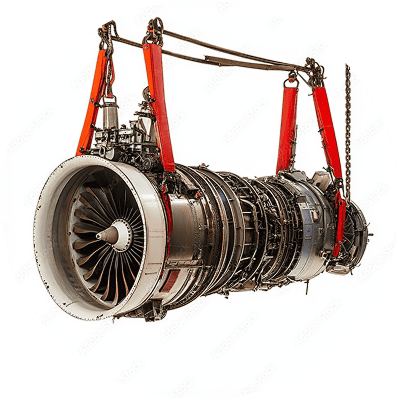

- Post-Emulsifiable – Lipophilic (Method B): Requires an oil-based emulsifier to render the penetrant removable by water. Offers high sensitivity and controlled removal, especially useful in aerospace applications.

- Post-Emulsifiable – Hydrophilic (Method D): Uses a water-based emulsifier, often in an immersion tank, for precise control over penetrant removal. Ideal for fine flaw detection.

- Solvent-Removable (Method C): Excess penetrant is wiped away using a solvent on lint-free cloths. Often used for localized inspection, field work, or where water use is limited.

Each method is selected based on application-specific needs, balancing sensitivity, process speed, and environmental constraints.

- Aerospace Components: Turbine blades, landing gear, and engine housings.

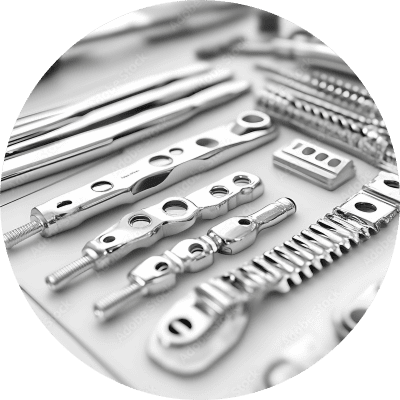

- Medical Devices: Orthopedic implants and surgical instruments.

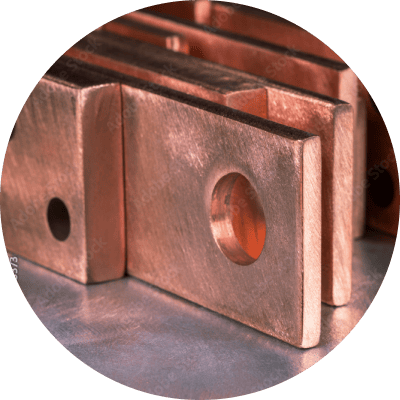

- Welded Assemblies: Revealing surface cracks in pressure-retaining components.

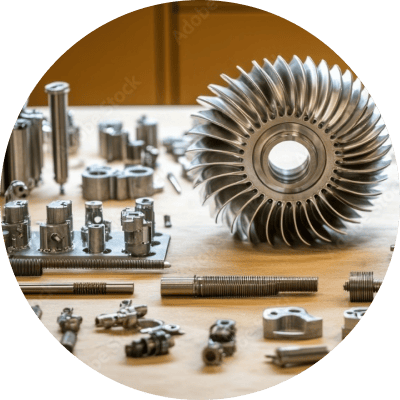

- High-Precision Parts: Inspection of machined or cast components prior to finishing

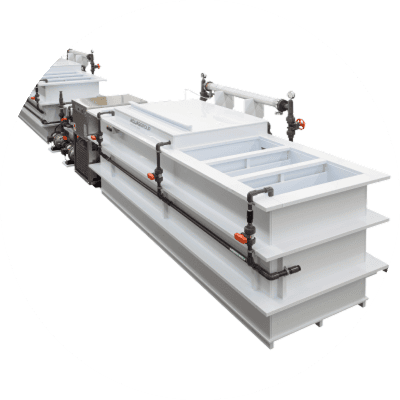

Water plays a vital role in both the pre- and post-cleaning phases, as well as during rinse steps after penetrant removal.

- Deionized (DI) Water Rinse: Prevents contamination that can interfere with defect visibility or leave residues.

- Closed-Loop Water Recycling: Maintains consistent rinse water quality while minimizing waste and reducing operational costs.

Tightly controlling variables in the FPI process ensures accurate, repeatable inspections and eliminates false indications.

- Consistency: Standardized dwell times and application techniques ensure reliable defect detection.

- Quality: Precise control over cleaning, rinsing, and development improves flaw visibility and interpretation.

- Efficiency: Optimized workflows reduce rework, increase throughput, and improve safety.

AQUASGROUP FPI systems are purpose-built to deliver controlled, high-throughput inspection with maximum reliability.

- Dedicated Process Chambers: Segregated stations for cleaning, penetration, development, and rinsing.

- UV Inspection Booths: Designed with optimal lighting and shielding for clear flaw detection.

- Effective Agitation: Promotes thorough cleaning and even penetrant application.

- Precise Temperature and Dwell Controls: Ensures standardized process parameters.

- Closed-Loop Water Systems: Integrated rinse water purification and reuse systems for sustainability and compliance.

- Custom Configurations: Engineered to meet aerospace, medical, and manufacturing specifications and footprint requirements.

FPI rinsewater recycling system

Proven Experience Since 1986

Since 1986, AQUASGROUP has delivered thousands of advanced process systems to major companies worldwide. Our FPI systems are trusted for their precision, reliability, and long-term performance in high-stakes applications where quality cannot be compromised.

Mailing Address:

Corporate Headquarters & Fabrication Division

41 Commercial Way

East Providence, RI 02914

Water Technologies & Service Division

830 Waterman Avenue

East Providence, RI 02914