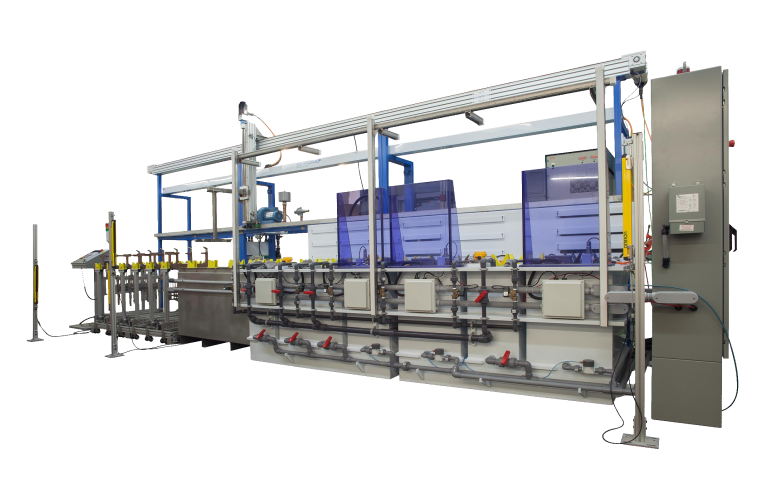

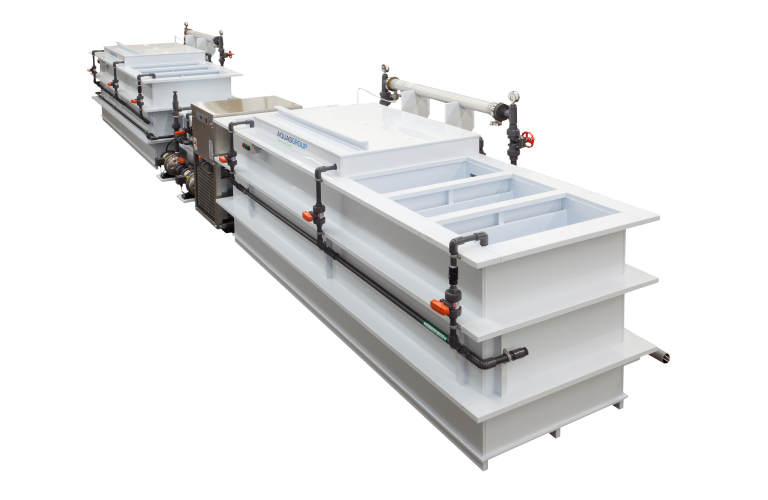

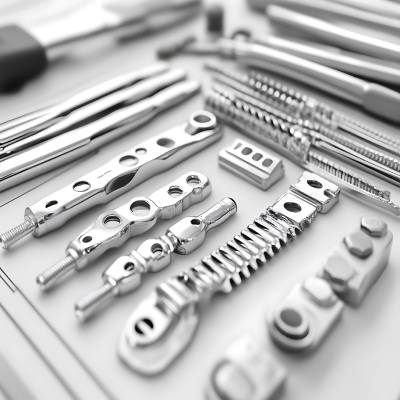

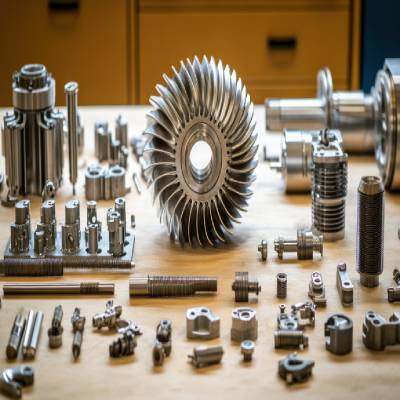

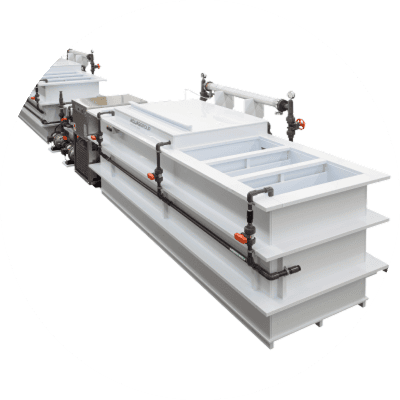

Manual and Automated Metal Finishing Systems

Engineered for Performance

Mailing Address:

Corporate Headquarters & Fabrication Division

41 Commercial Way

East Providence, RI 02914

Water Technologies & Service Division

830 Waterman Avenue

East Providence, RI 02914