Smart Design. Efficient Operation. Reliable Results. Since 1986

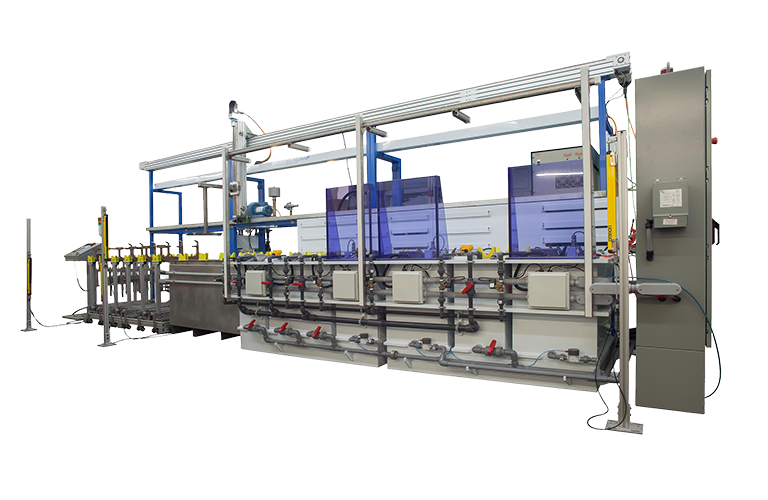

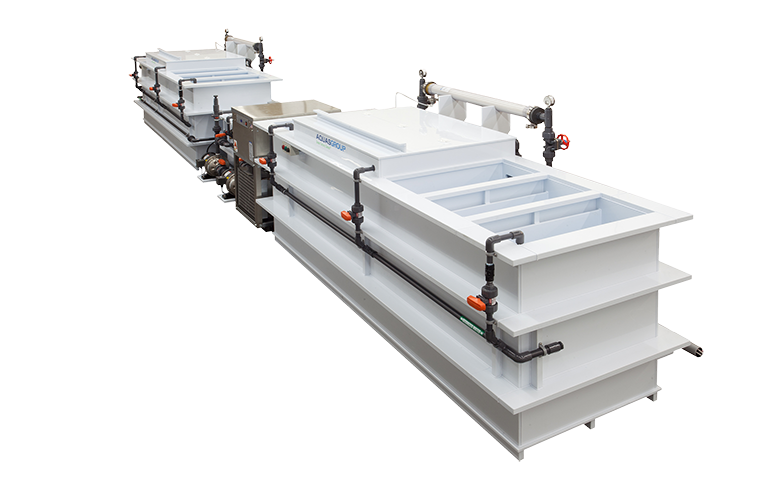

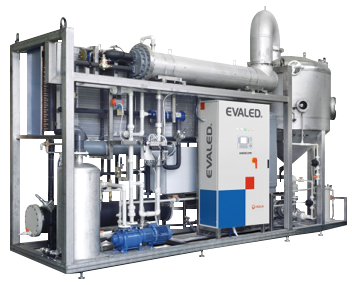

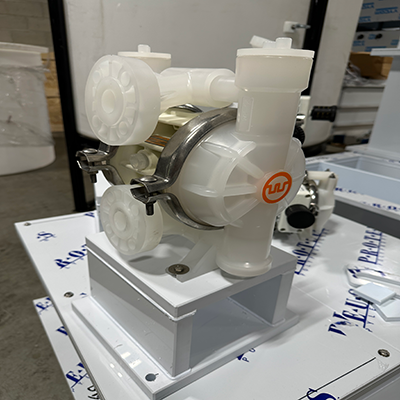

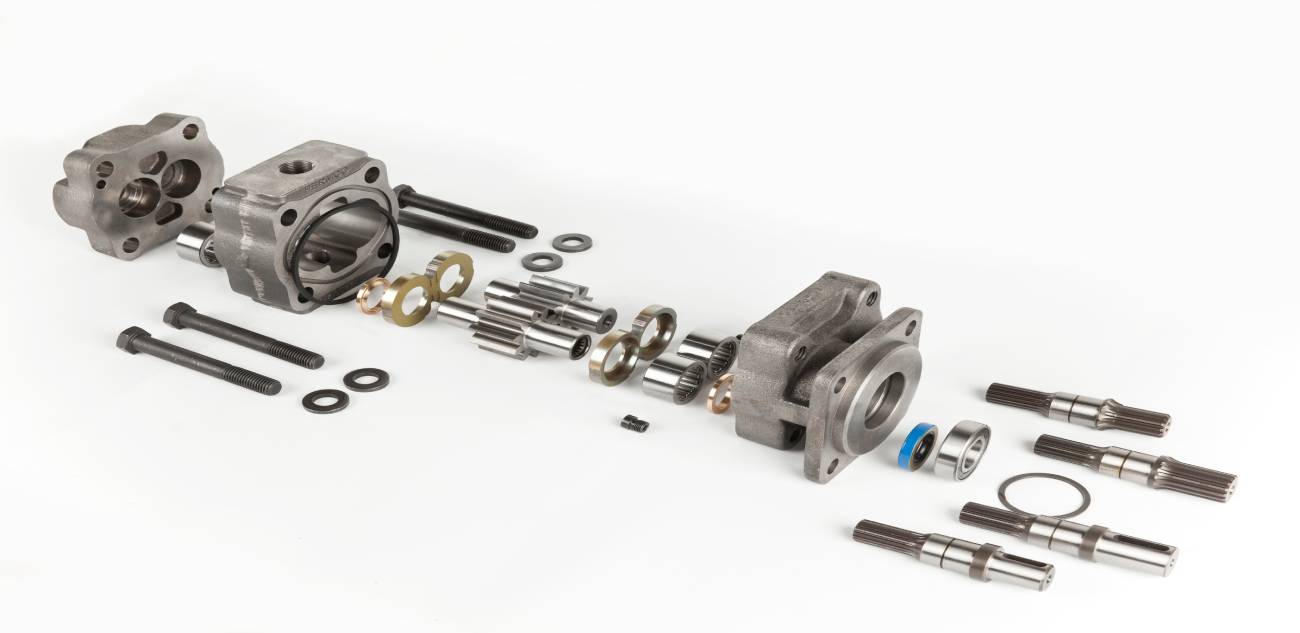

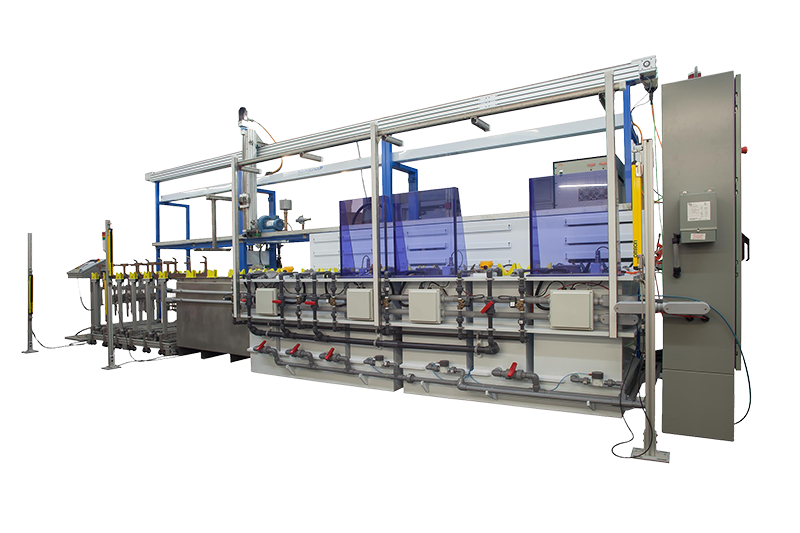

AQUASGROUP is a design/build manufacturer of chemical process lines, industrial parts washing and flushing systems, and comprehensive water treatment systems for precision manufacturing sectors. With in-house mechanical, electrical, and chemical engineering capabilities, we deliver solutions that enhance product quality, system reliability, and operational efficiency. We support OEMs and suppliers across regulated, high-performance industries:

Design/Build Partner

One source for engineering, fabrication, and integration

Sustainability Focused

Reduce water, energy, and chemical consumption

Full Lifecycle Support

From design, build, and installation to upgrades, replacement parts, and preventive maintenance

Custom Industrial Equipment Built for Your Process

Built for the Needs of Precision Manufacturers

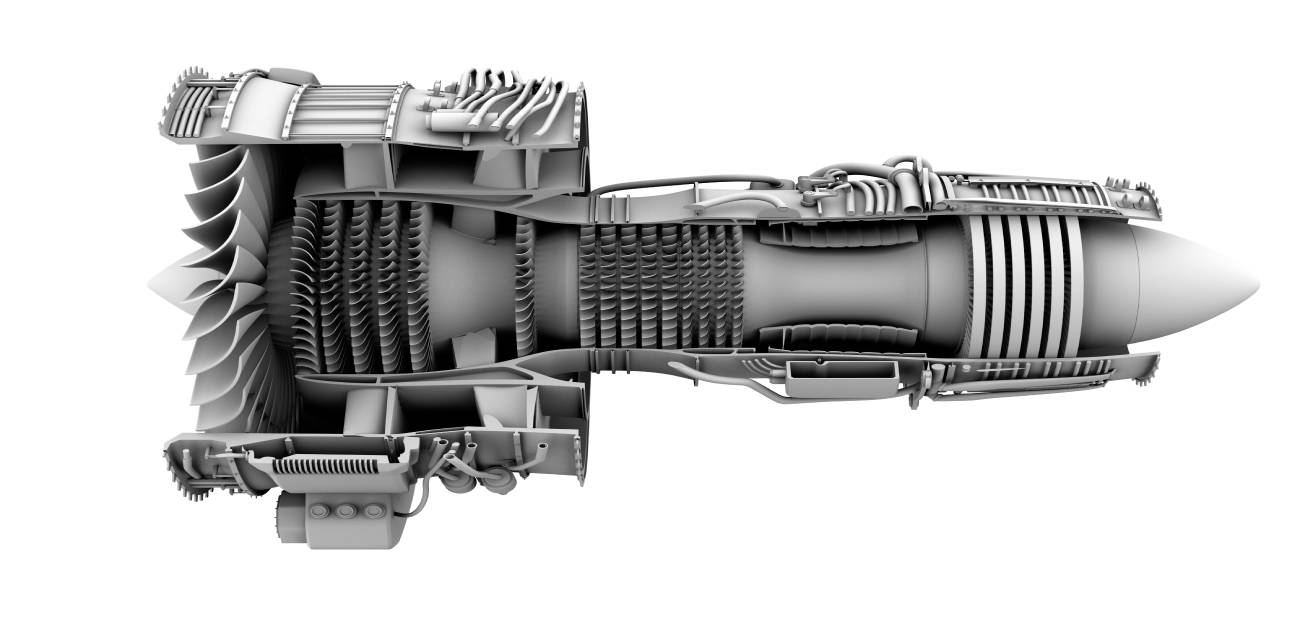

We support OEMs and suppliers across regulated, high-performance industries:

AQUASGROUP Occupies New Corporate Headquarters, Expanding Services and Production Capacity

East Providence, August 23, 2023 – AQUASGROUP is excited to announce the relocation of ...

AQUASGROUP Closes on New East Providence Facility

AQUASGROUP recently closed on a new facility in East Providence, RI adding 25,000sq.ft of high ...

TECH+ NOTES

How to Select Your Next Parts Washer

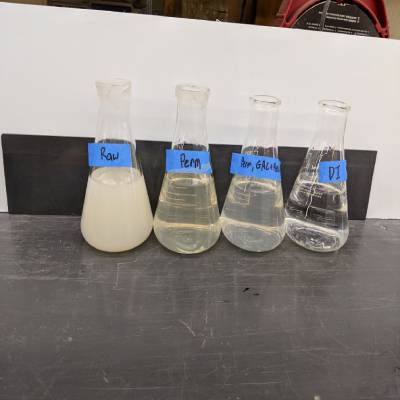

In order to cost effectively recycle water, it is critical that the parts washer design makes efficient use of detergent, thereby minimizing the amount that the rinse water needs to remove. Enhanced immersion and spray over immersion designs provide the answer to most applications.

The Advantages of Green Manufacturing in the Metal Finishing Sector

Metal Finishing benefits society by making inexpensive metals durable.

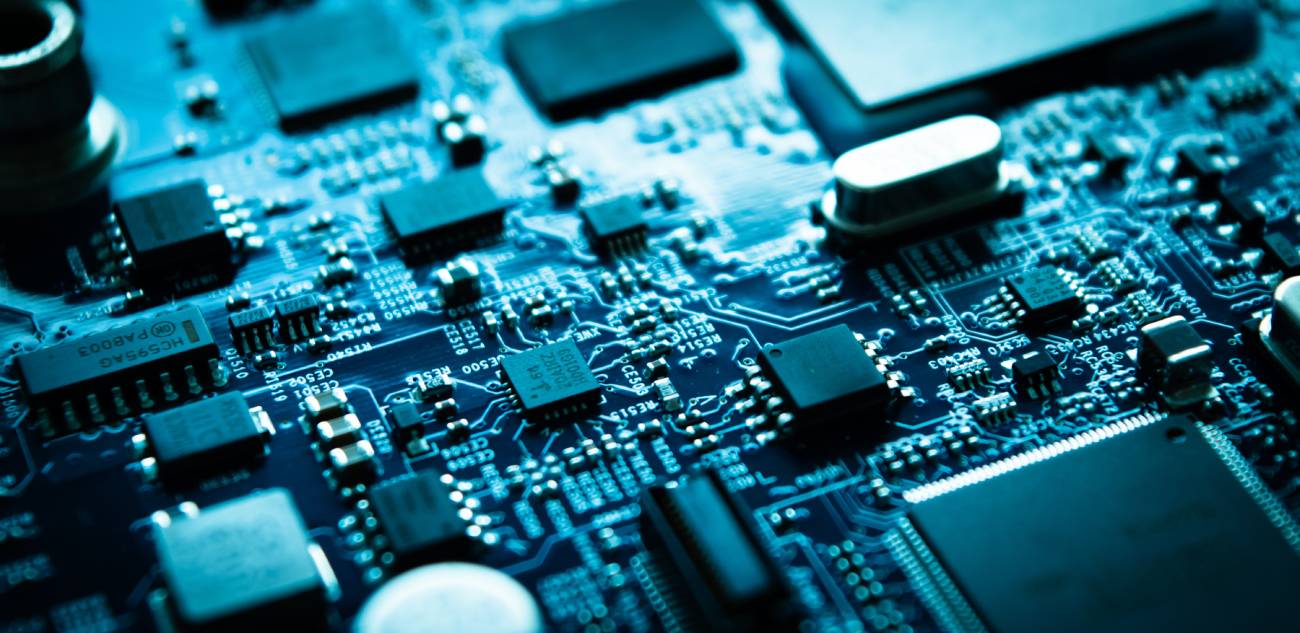

For example, anodizing, passivating and plating minimize or eliminate the potential for corrosion. This translates to the reliability of things like electrical circuits, building materials, medical devices , aircraft and automobiles. We need this, but we also need to safeguard our air and water supplies.